13T Excavator Sprocket

Description: PC200

Function:undercarriage spare parts of excavator ,suitable for RM excavator

Material:SCMnMoH

Heart treatment requirement: quenching and tempering,medium frequency

Brand:OEM

An excavator sprocket is an important component of the undercarriage system on an excavator. It is located on the final drive unit and works in conjunction with the track chain to propel and support the excavator.

The sprocket has teeth that mesh with the links of the track chain, providing traction and allowing the excavator to move forward or backward. As the sprocket rotates, it engages and advances the track chain, enabling the excavator to maneuver and operate.

The excavator sprocket is typically made of high-strength steel to withstand the heavy loads and harsh operating conditions. It is designed to be durable and long-lasting, as it experiences constant wear and tear from the friction between the sprocket teeth and the track chain links.

Regular maintenance and inspection of the sprocket are essential to ensure optimal performance and to identify any signs of wear or damage. If a sprocket becomes worn or damaged, it should be replaced promptly to avoid further damage to the undercarriage system and to maintain the efficiency and safety of the excavator.

In summary, an excavator sprocket is a crucial component of an excavator's undercarriage system. It works in tandem with the track chain to provide traction and allow the excavator to move. Proper maintenance and replacement when necessary are essential to ensure the excavator's smooth operation.

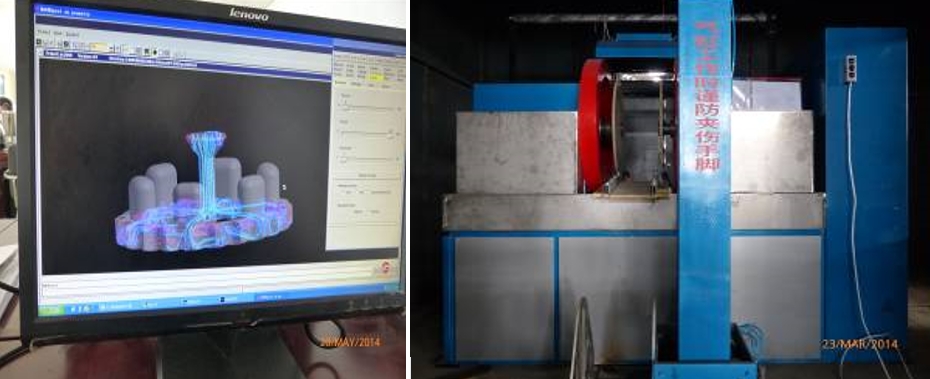

Test equipment